RBF Neural Network in Electrostatic Levitation Position Control

-

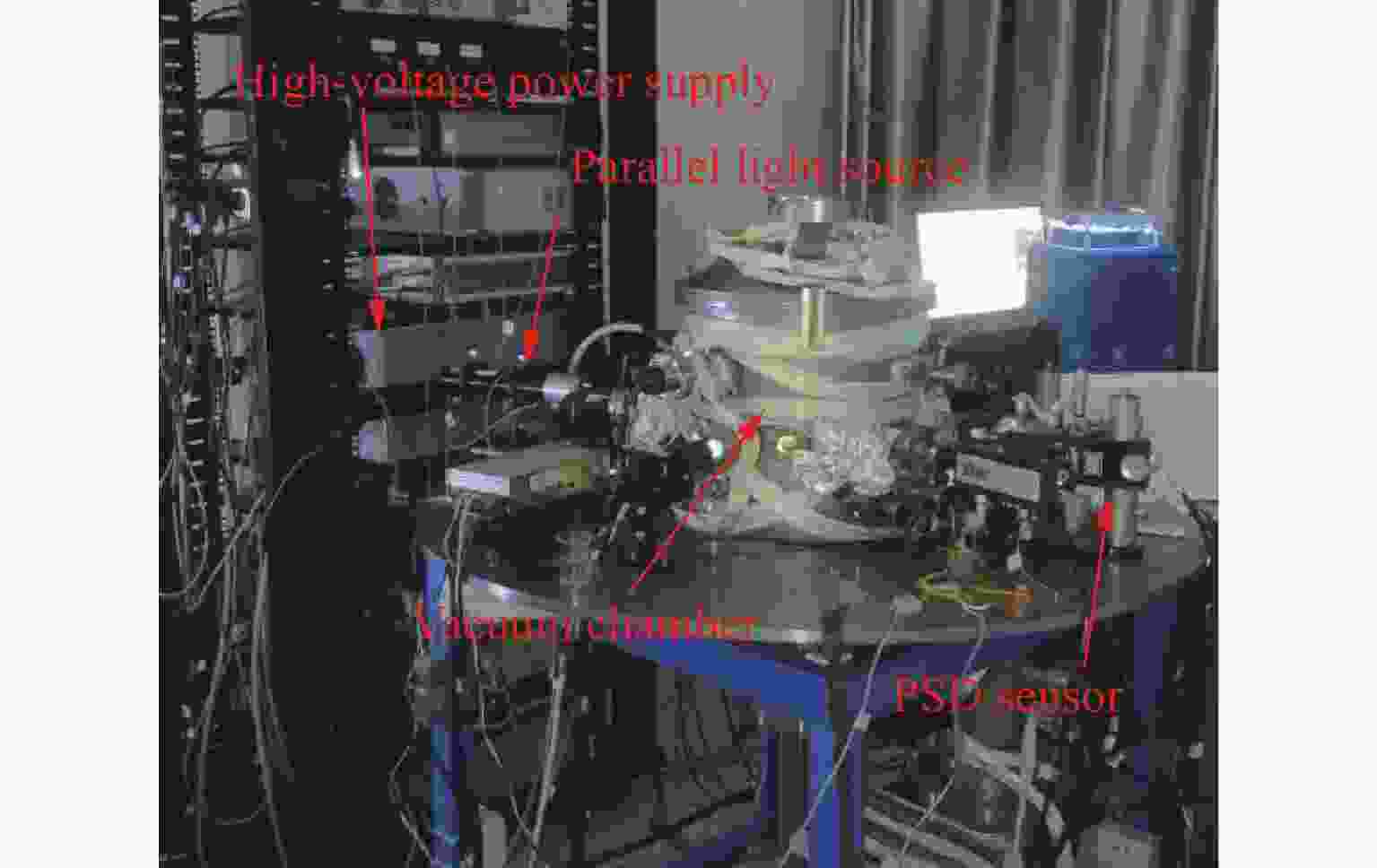

摘要: 静电悬浮位置控制系统具有非线性、时变性的特点,传统的控制方法不能有效抑制扰动的影响。针对该问题提出了一种神经网络与PID相结合的RBF-PID控制策略。以球形样品为例分析其受力情况,推导出静电悬浮位置控制系统的机理模型。搭建基于RBF-PID控制器的静电悬浮位置控制系统,并根据仿真结果实时在线调整控制参数。仿真结果表明,当样品带电量从10–9 C突变至3×10–9 C时,RBF-PID控制器只需0.12 s即可使样品达到稳定状态。实验结果表明,当样品处于加热状态时,实时调整参数后系统的平均绝对误差为0.0416 mm,控制效果比传统PID控制策略提高了70%。所提出的控制方法辨识精度高,具有比传统PID方法更强的鲁棒性和稳定性。Abstract: With the characteristics of nonlinearity and time variation, the position control system of electrostatic levitation facility cannot suppress the disturbance effectively by using traditional control methods. To solve this problem, a RBF-PID control strategy combining neural network and PID control method was proposed. Firstly, the mechanical analysis on the spherical sample was researched, and the mechanism model of the position control system of electrostatic levitation was deduced. Then, the position control system of electrostatic levitation was constructed, based on the RBF-PID controller. The control parameters were adjusted in real-time according to the simulation results. The simulation results show that it takes 0.12 s to make the sample stable when its surface charge suddenly changes from 10–9 C to 3×10–9 C. The experimental results show that when the sample is in the heated status, the mean absolute error of control system is 0.0416 mm by adjusting the parameters in real time, and the control effect is 70% better than that of traditional PID controller .The proposed RBF-PID control strategy has a high identification accuracy, and it has stronger robustness and stability compared with the traditional PID control strategy.

-

Key words:

- Electrostatic levitation /

- Position control system /

- RBF neural network

-

表 1 系统仿真参数

Table 1. Parameters of system simulation

系统参数 非线性系统

参数值线性系统

参数值样品质量/mg 26 26 上下电极间距/mm 10 10 样品带电量/C 10–9 10–9 学习速率 η 30 70 动量因子 α 0.04 0.09 参数P学习速率 ηp 500 700 参数I学习速率 ηi 850 950 参数D学习速率 ηd 350 490 表 2 仿真结果对比

Table 2. Comparison of simulation results

样品电荷量突变值/C 0.5×10–9 2×10–9 3×10–9 最大

误差

/mm稳定

时间

/s振荡

情况最大

误差

/mm稳定

时间

/s振荡

情况最大

误差

/mm稳定

时间

/s振荡

情况传统PID 0.247 8.6 剧烈 0.126 0.242 较大 0.170 0.249 较大 最优整定PID 0.176 0.226 无 0.083 0.138 较小 0.112 0.173 较小 RBF-PID 0.174 0.118 无 0.079 0.110 无 0.125 0.122 无 表 3 实验结果对比

Table 3. Comparison of experimental results

控制器 室温 加热 误差范围

/mm平均绝对

误差/mm误差范围

/mm平均绝对

误差/mm传统PID –0.130~0.110 0.0384 –0.430~0.690 0.1879 最优整定PID –0.080~0.110 0.0269 –0.143~0.296 0.0685 RBF-PID –0.095~0.080 0.0172 –0.140~0.185 0.0416 -

[1] 孙一宁, 王飞龙, 于强, 等. 静电悬浮条件下的材料典型热物理性质测量[J]. 材料导报, 2016, 30(S2): 253-258SUN Yining, WANG Feilong, YU Qiang, et al. Thermophysical property measurements by electrostatic levitation in material science[J]. Materials Review, 2016, 30(S2): 253-258 [2] WANG F L, DAI B, LIU X F, et al. Containerless heating process of a deeply undercooled metal droplet by electrostatic levitation[J]. Chinese Physics Letters, 2015, 32(11): 114101 doi: 10.1088/0256-307X/32/11/114101 [3] MOHR M, WUNDERLICH R K, KOCH S, et al. Surface tension and viscosity of Cu50Zr50 measured by the oscillating drop technique on board the international space station[J]. Microgravity Science and Technology, 2019, 31(2): 177-184 doi: 10.1007/s12217-019-9678-1 [4] China Manned Space. High quality domestic products, strong as the sky![EB/OL]. (2021-07-21)[2021-09-25]. http://www.cmse.gov.cn/kjkx/kjkxyjyyy/202107/t20210726_48473.html [5] RULISON A J, WATKINS J L, ZAMBRANO B. Electrostatic containerless processing system[J]. Review of Scientific Instruments, 1997, 68(7): 2856-2863 doi: 10.1063/1.1148208 [6] ISHIKAWA T, KOYAMA C, PARADIS P F, et al. Densities of liquid Re, Os, and Ir, and their temperature dependence measured by an electrostatic levitator[J]. International Journal of Refractory Metals and Hard Materials, 2020, 92: 105305 doi: 10.1016/j.ijrmhm.2020.105305 [7] HERLACH D. Crystal nucleation and dendrite growth of metastable phases in undercooled melts[J]. Journal of Alloys and Compounds, 2011, 509(S1): S13-S17 [8] LEE G W, JEON S, PARK C, et al. Crystal-liquid interfacial free energy and thermophysical properties of pure liquid Ti using electrostatic levitation: Hypercooling limit, specific heat, total hemispherical emissivity, density, and interfacial free energy[J]. The Journal of Chemical Thermodynamics, 2013, 63: 1-6 doi: 10.1016/j.jct.2013.03.012 [9] HU L, WANG H P, XIE W J, et al. Electrostatic levitation under the single-axis feedback control condition[J]. Science China Physics, Mechanics and Astronomy, 2010, 53(8): 1438-1444 doi: 10.1007/s11433-010-4068-0 [10] ZOU Z Z, LUO X H, YU Q. Droplet image super resolution based on sparse representation and kernel regression[J]. Microgravity Science and Technology, 2018, 30(3): 321-329 doi: 10.1007/s12217-018-9597-6 [11] 陈东阳, 郭清远, 董文博, 等. 基于高速视觉的静电悬浮控制系统[J]. 光学 精密工程, 2019, 27(11): 2343-2353 doi: 10.3788/OPE.20192711.2343CHEN Dongyang, GUO Qingyuan, DONG Wenbo, et al. Control system of electrostatic levitation based on high-speed vision[J]. Optics and Precision Engineering, 2019, 27(11): 2343-2353 doi: 10.3788/OPE.20192711.2343 [12] NAKAMURA T, AWA Y, SHIMOJI H, et al. Control system of electrostatic levitation furnace[J]. Acta Astronautica, 2002, 50(10): 609-614 doi: 10.1016/S0094-5765(01)00219-3 [13] MEISTER T, WERNER H, LOHOEFER G, et al. Gain-scheduled control of an electrostatic levitator[J]. Control Engineering Practice, 2003, 11(2): 117-128 doi: 10.1016/S0967-0661(02)00102-8 [14] NUELLA I, CHENG C, CHIU M S. Adaptive PID controller design for nonlinear systems[J]. Industrial & Engineering Chemistry Research, 2009, 48(10): 4877-4883 [15] QIAO J F, LI F, YANG C L, et al. A self-organizing RBF neural network based on distance concentration immune algorithm[J]. IEEE/CAA Journal of Automatica Sinica, 2020, 7(1): 276-291 doi: 10.1109/JAS.2019.1911852 [16] 郭益深, 陈力. 漂浮基姿态受控空间机械臂关节运动的自适应神经网络控制[J]. 空间科学学报, 2008, 28(2): 173-179 doi: 10.11728/cjss2008.02.173GUO Yishen, CHEN Li. Adaptive neural network control of free-floating space manipulator with an attitude controlled base[J]. Chinese Journal of Space Science, 2008, 28(2): 173-179 doi: 10.11728/cjss2008.02.173 [17] RAHIMZADEH H, SADEGHI M, GHASEMI-VARNAMKHASTI M, et al. On the feasibility of metal oxide gas sensor based electronic nose software modification to characterize rice ageing during storage[J]. Journal of Food Engineering, 2019, 245: 1-10 doi: 10.1016/j.jfoodeng.2018.10.001 [18] LI Y, LIU M Y, ZHANG X J, et al. Global approximation based adaptive RBF neural network control for supercavitating vehicles[J]. Journal of Systems Engineering and Electronics, 2018, 29(4): 797-804 doi: 10.21629/JSEE.2018.04.14 [19] MUNRO K, MILLER T H, MARTINS C P B, et al. Artificial neural network modelling of pharmaceutical residue retention times in wastewater extracts using gradient liquid chromatography-high resolution mass spectrometry data[J]. Journal of Chromatography A, 2015, 1396: 34-44 doi: 10.1016/j.chroma.2015.03.063 [20] 周扬扬, 韦韧, 王超, 等. 静电悬浮位置控制系统设计与实现[J]. 空间科学学报, 2011, 31(5): 675-681 doi: 10.11728/cjss2011.05.675ZHOU Yangyang, WEI Ren, WANG Chao, et al. Design and implementation of electrostatic levitation position control system[J]. Chinese Journal of Space Science, 2011, 31(5): 675-681 doi: 10.11728/cjss2011.05.675 [21] LIU N J, CAI Z H, ZHAO J, et al. Predictor-based model reference adaptive roll and yaw control of a quad-tiltrotor UAV[J]. Chinese Journal of Aeronautics, 2020, 33(1): 282-295 doi: 10.1016/j.cja.2019.08.001 [22] 李明, 封航, 张延顺. 基于UMAC的RBF神经网络PID控制[J]. 北京航空航天大学学报, 2018, 44(10): 2063-2070 doi: 10.13700/j.bh.1001-5965.2017.0777LI Ming, FENG Hang, ZHANG Yanshun. RBF neural network tuning PID control based on UMAC[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(10): 2063-2070 doi: 10.13700/j.bh.1001-5965.2017.0777 [23] ATTARAN S M, YUSOF R, SELAMAT H. A novel optimization algorithm based on epsilon constraint-RBF neural network for tuning PID controller in decoupled HVAC system[J]. Applied Thermal Engineering, 2016, 99: 613-624 doi: 10.1016/j.applthermaleng.2016.01.025 [24] SHI K J, LI B, WANG F M, et al. Research on the RBF-PID control method for the motor actuator used in a UHV GIS disconnector[J]. The Journal of Engineering, 2019, 2019(16): 2013-2017 doi: 10.1049/joe.2018.8728 -

-

下载:

下载: