Dynamic Characteristics of Airship Envelope Material with Concentrated Mass

-

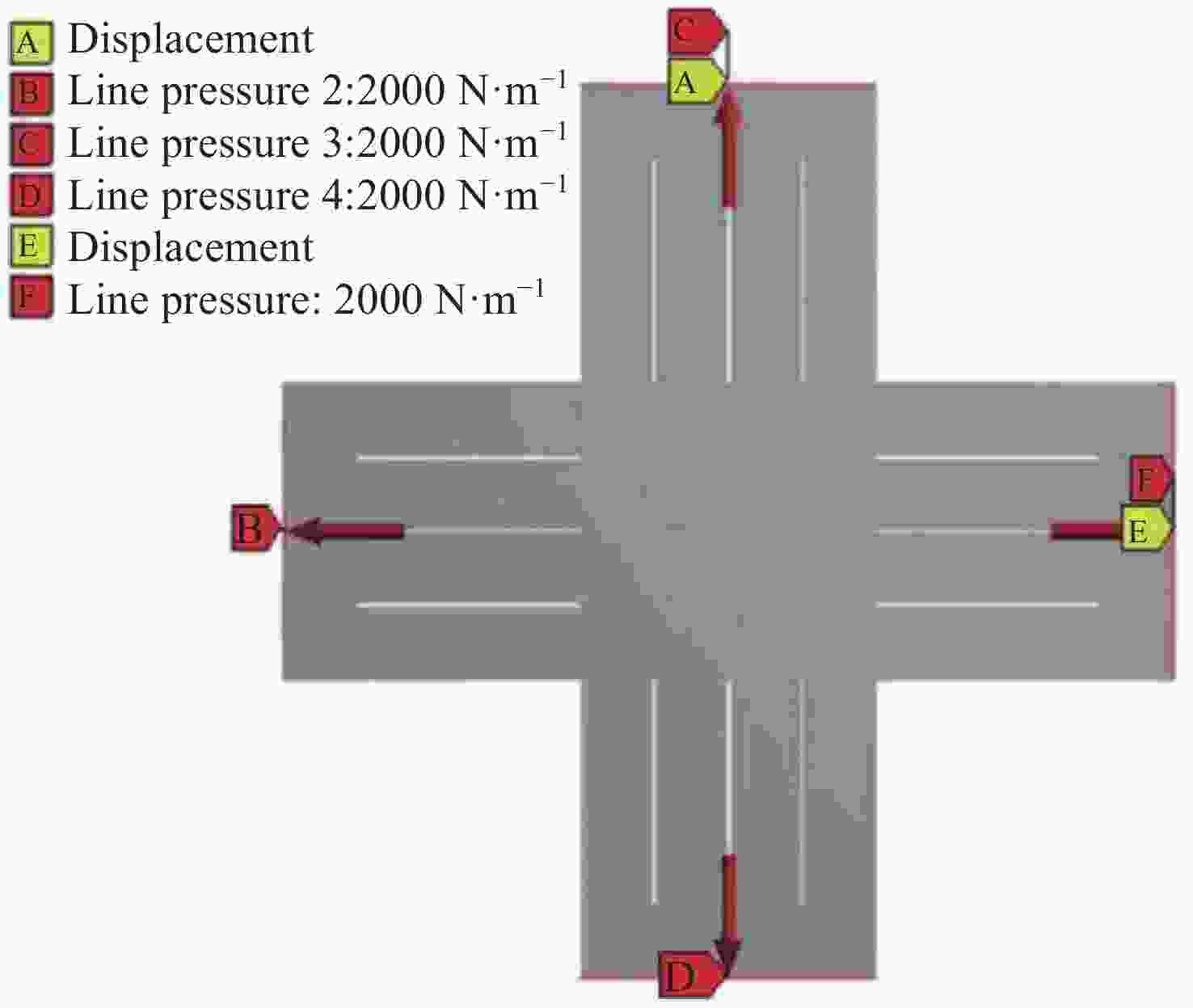

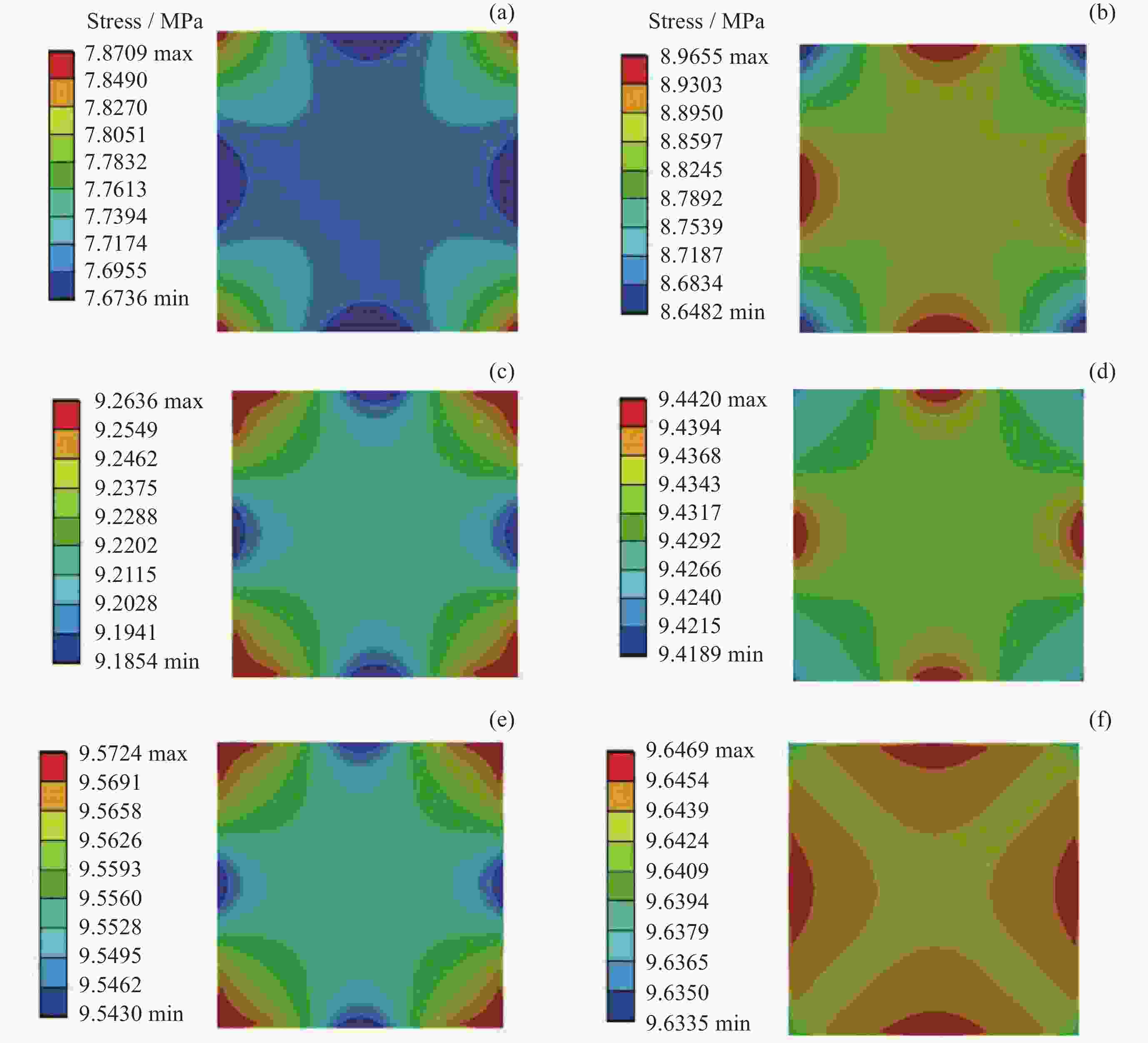

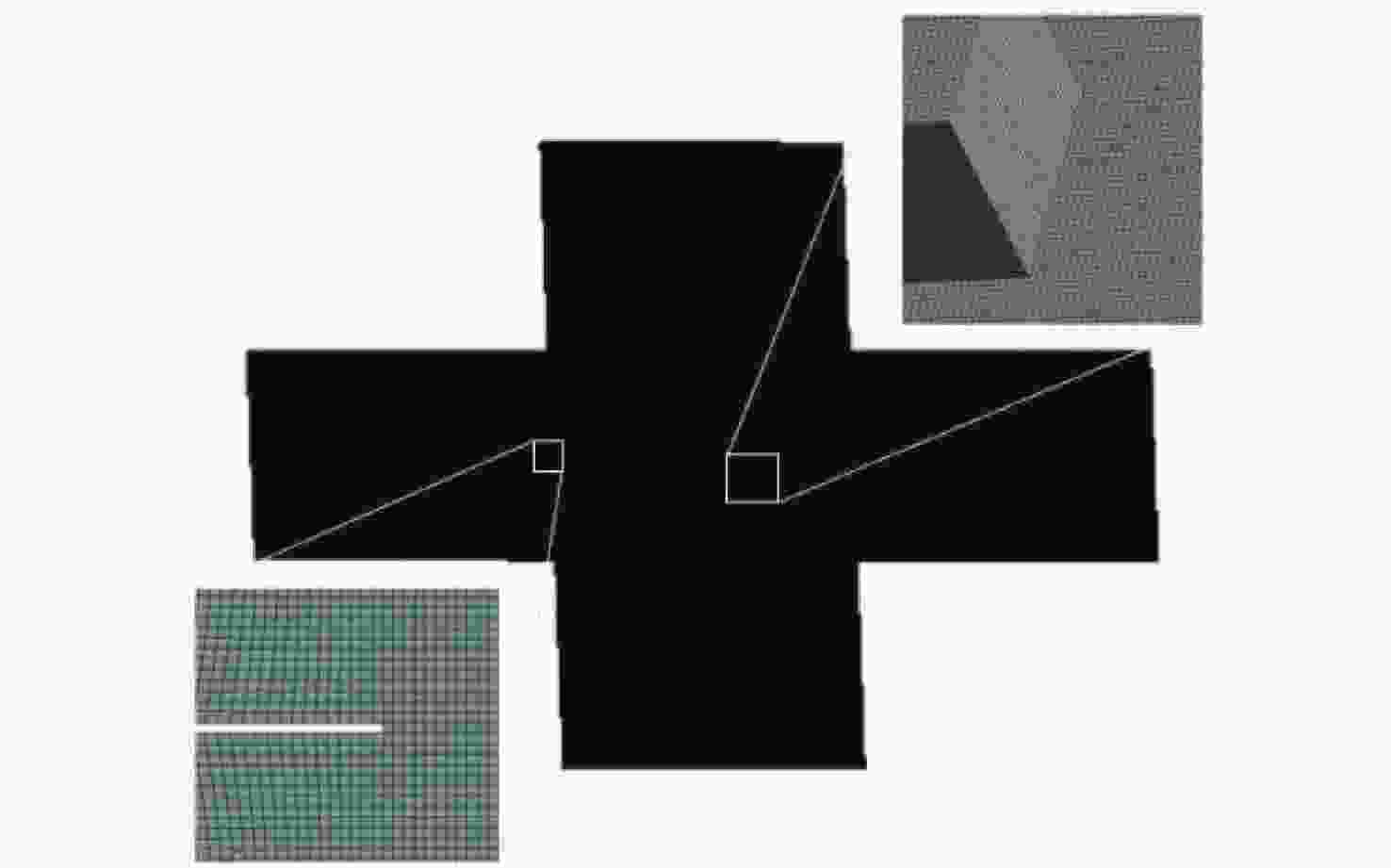

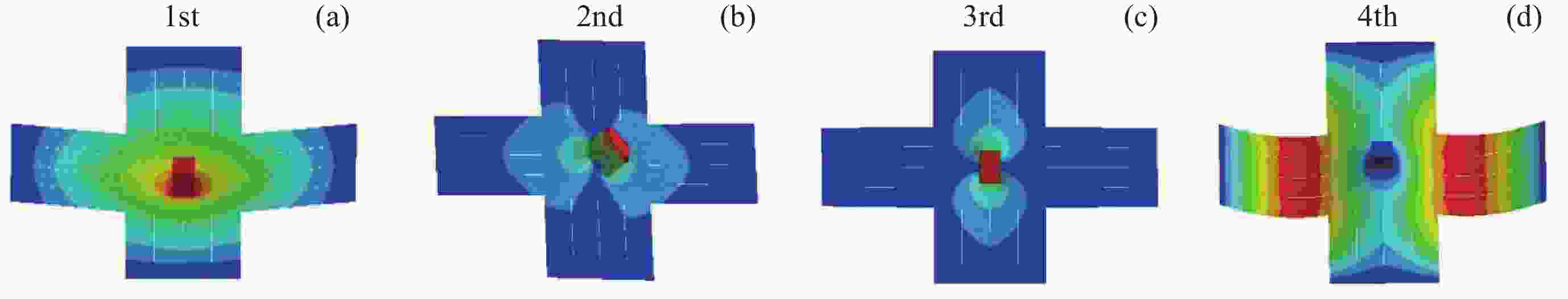

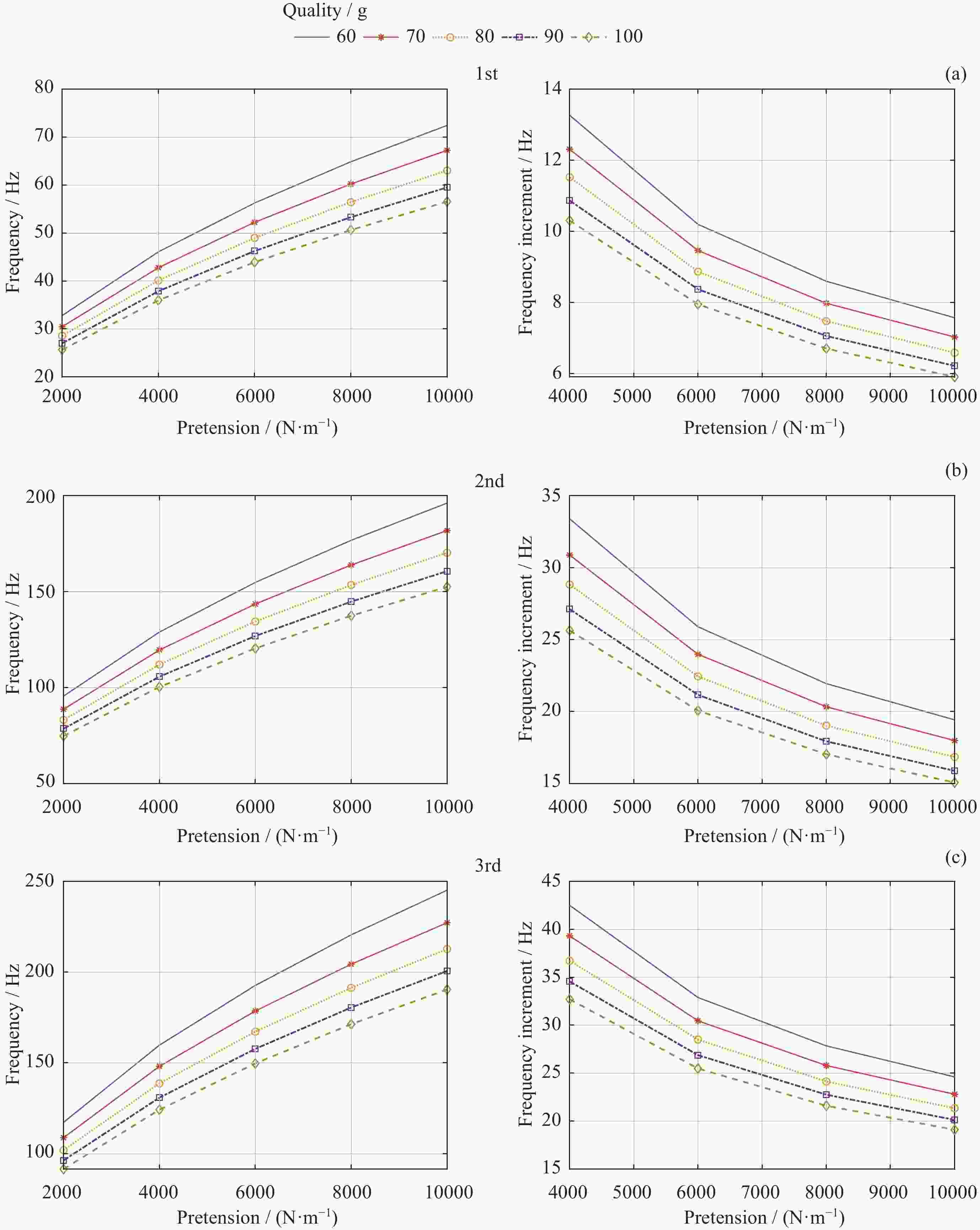

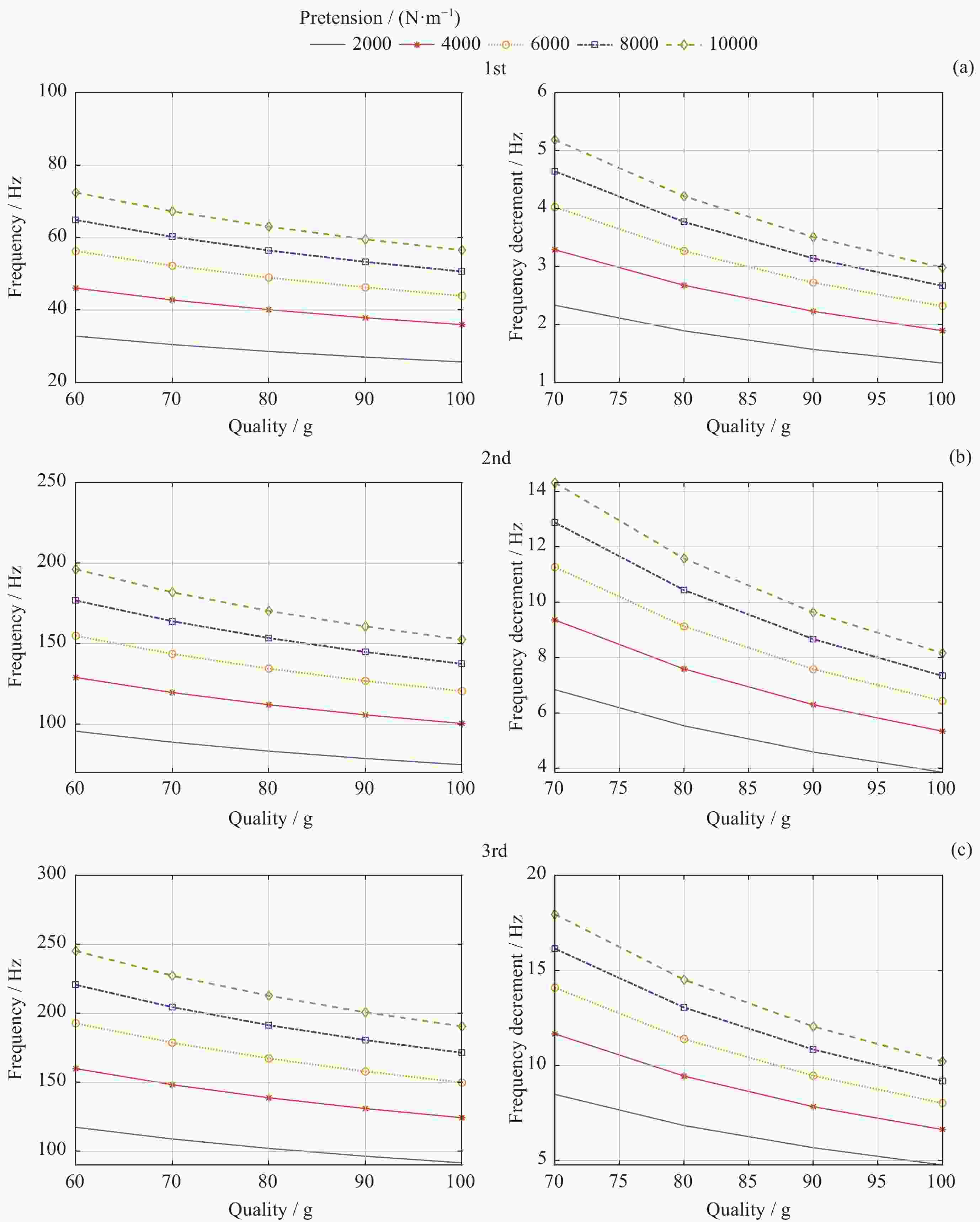

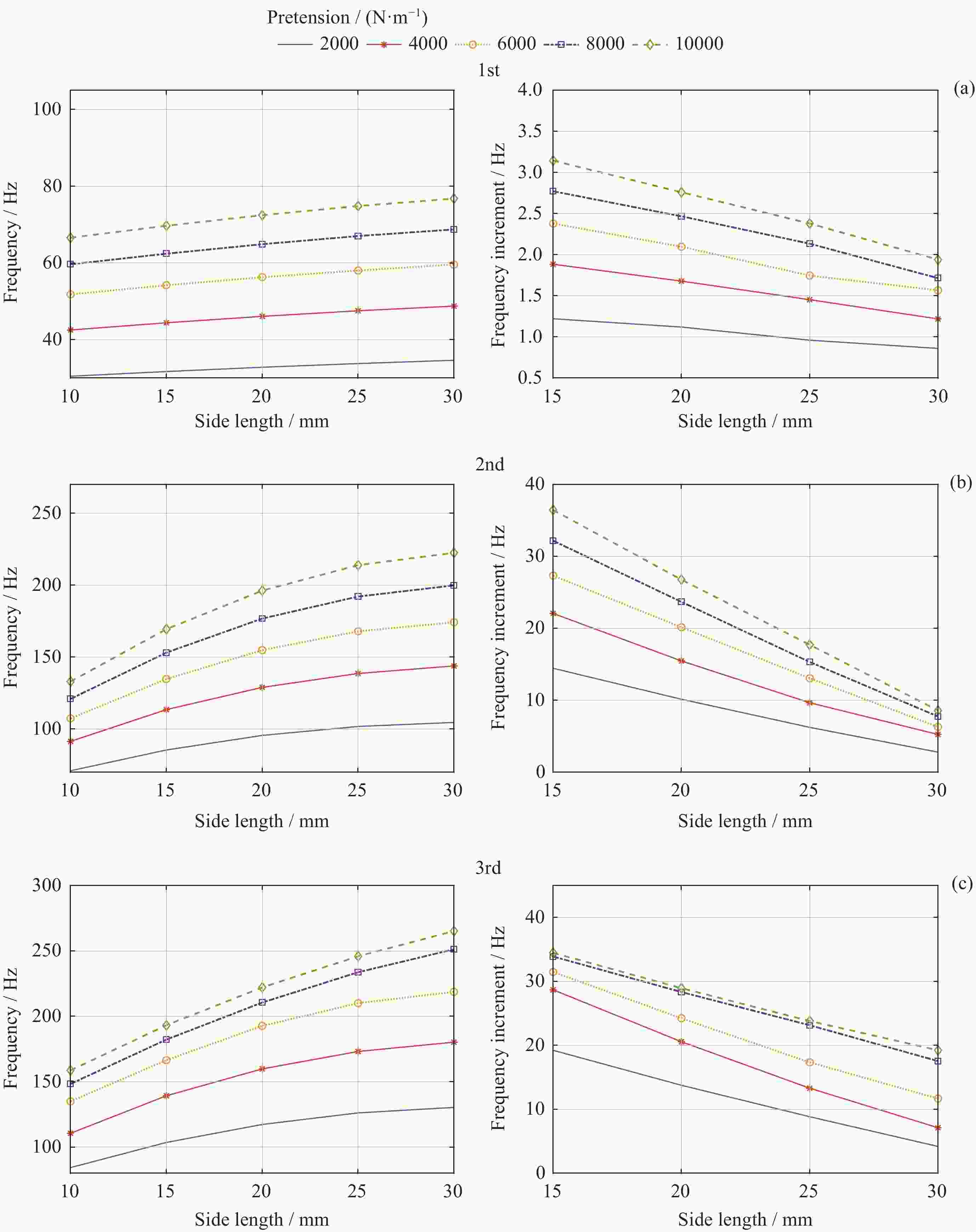

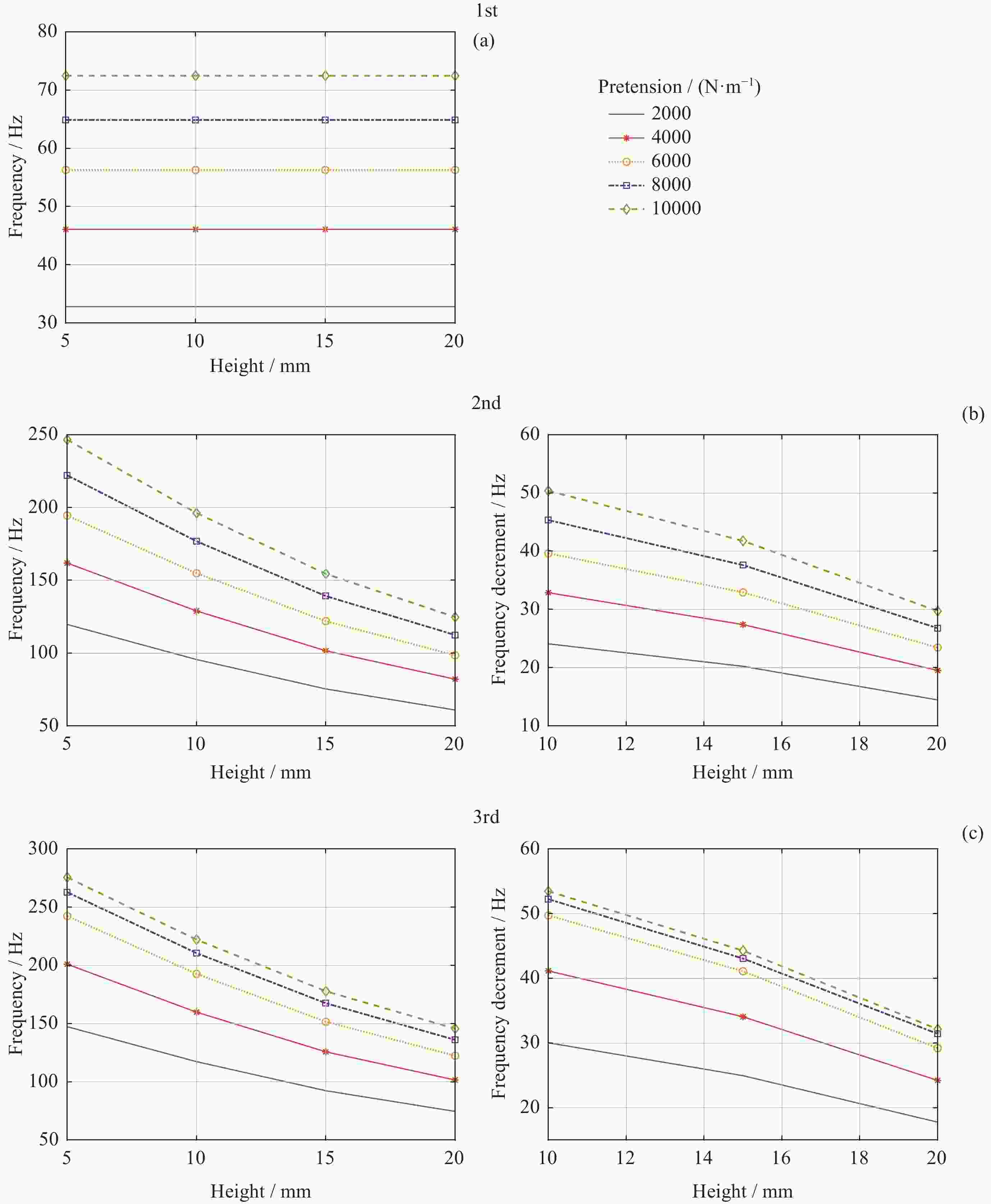

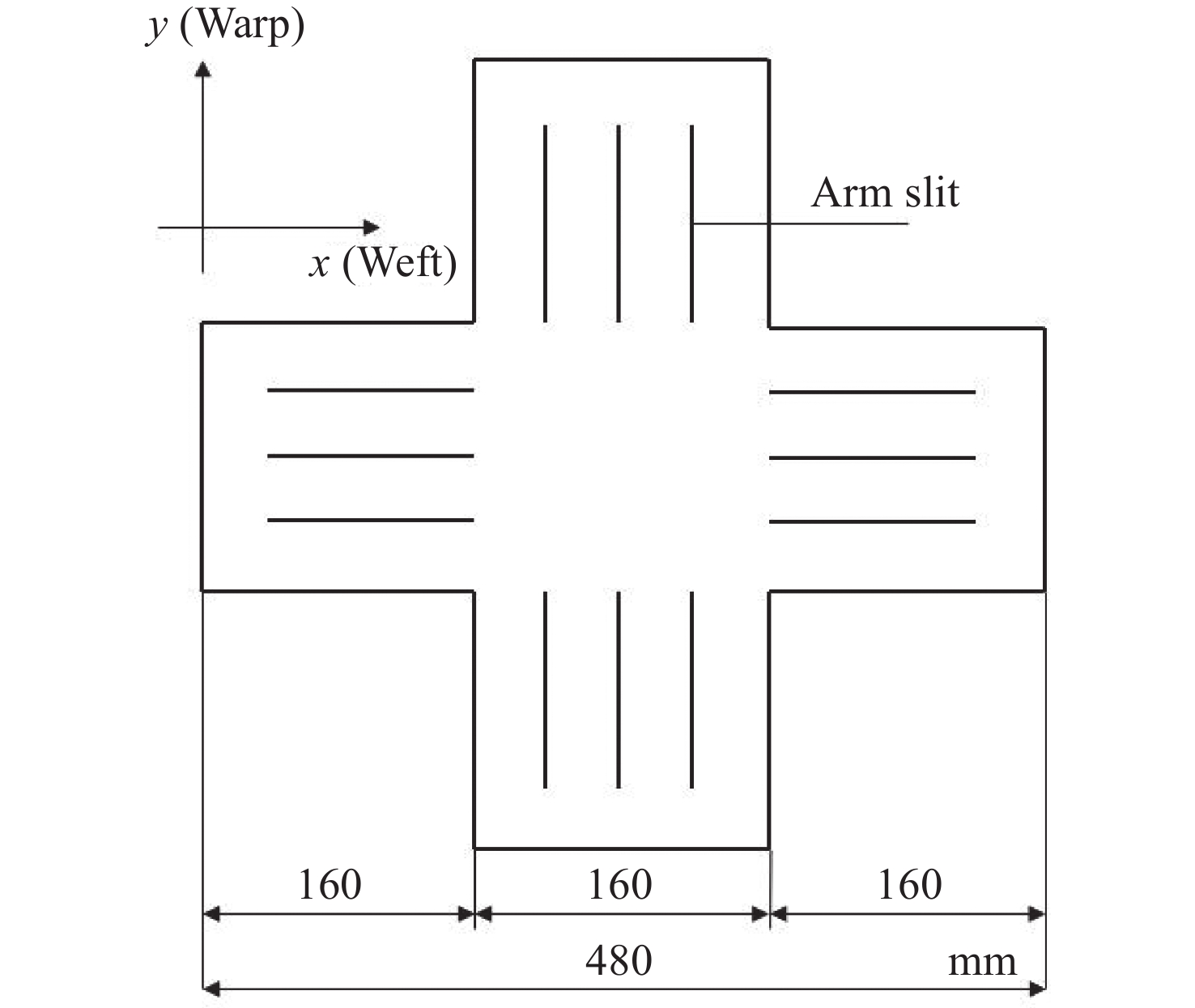

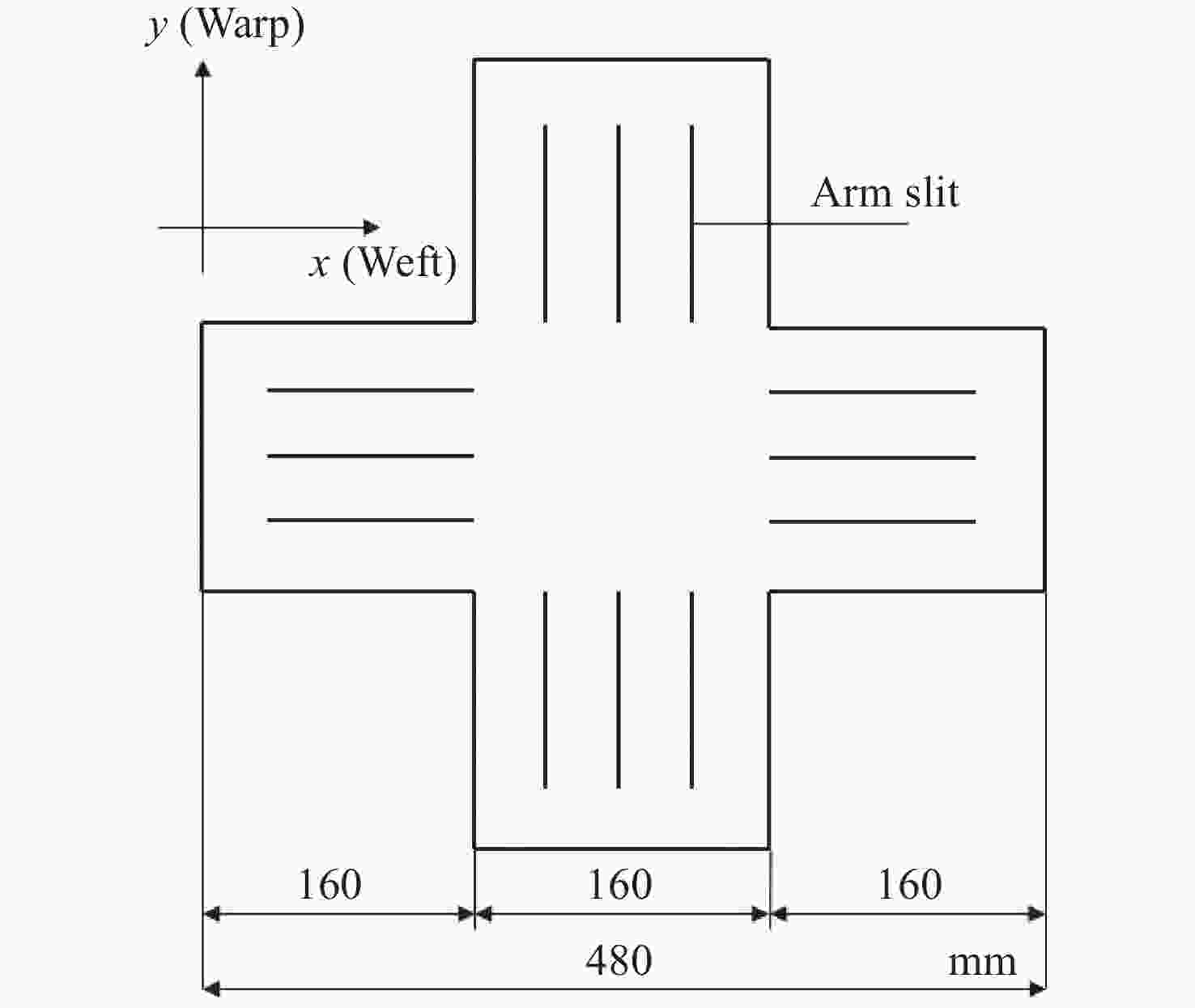

摘要: 针对平流层飞艇刚柔一体大型复杂结构系统设计与分析, 开展了附有集中质量的飞艇囊体材料动力特性仿真分析研究, 将刚度大、质量相对集中的结构零部件简化为集中质量, 飞艇囊体简化为双向拉伸的十字形囊体材料试样, 分析预张力大小、集中质量的质量和尺寸对囊体材料试样的动力特性影响. 结果表明, 试样的固有频率随着预张力增大而增大, 随着集中质量的质量增大而减小, 随着集中质量与试样连接的边长增加而增大; 试样的基频与集中质量的高度无关, 但第2, 3阶频率随着集中质量的高度增加而减小. 研究结论为飞艇结构的总体设计与分析以及进一步开展附有集中质量的飞艇囊体材料动力试验提供了理论依据.Abstract: Aiming at the design and analysis of stratospheric airship rigid and flexible integrated large complex structure system, this paper carried out the simulation analysis of dynamic characteristics of airship envelope material with concentrated mass. The structural parts with high stiffness and relatively concentrated mass are simplified as concentrated mass. The airship envelope is simplified as a biaxially stretched cross envelope material sample. Firstly, the influences of the number of open arm slits on the stress transfer uniformity in the central region of the cross envelop material sample are analyzed. Then the influences of pretension, mass and concentrated mass of the size on the natural frequency of cross film material sample are analyzed. The influence of the mass and concentrated mass of the size on the natural frequency of the airship capsule is also reflected. The results show that the uniformity of stress transfer in the central region of the cross envelop material sample is better with the increase of the number of arm slits. When the number of arm slits is 3, the proportional coefficient of stress transfer uniformity is 0.943. In addition, the natural frequency of the sample increases with the pretension increase, decreases with the mass of the concentrated mass increase, and increases with the side length of the connection between the concentrated mass and the sample increase. The fundamental frequency of the sample is independent of the height of the concentrated mass, but the second and third order frequencies decrease with the height of the concentrated mass increase. The second and third order frequencies are significantly more affected by various physical quantities than the first order. Under the condition of the same pretension and mass, the influence of the height of the concentrated mass on the second and third order frequencies of the cross envelop sample is higher than that of the side length. The research results provide a theoretical basis for the overall design and analysis of airship structure and the further dynamic experiments of airship envelope materials with concentrated mass.

-

表 1 不同臂缝条数十字形试样的$q$值

Table 1. $q$ values of cross sample with different arm slits

臂缝条数 0 1 2 3 4 5 q 值 0.7772 0.8807 0.9225 0.9430 0.9558 0.9640 增幅/(%) — 13.3 4.7 2.2 1.4 0.9 -

[1] QIN P F, WANG X L. Construction on aerodynamic surrogate model of stratospheric airship[J]. Journal of Shanghai Jiaotong University (Science), 2022, 27(6): 768-779 doi: 10.1007/s12204-022-2494-6 [2] ZUO Z Y, SONG J W, ZHENG Z W, et al. A survey on modelling, control and challenges of stratospheric airships[J]. Control Engineering Practice, 2022, 119(4): 104979 [3] MA J, WEI Q, FAN H B, et al. Mechanical properties evolution and damage mechanism of kevlar fiber under ozone exposure in near-space simulation[J]. Coatings, 2022, 12(5): 584 doi: 10.3390/coatings12050584 [4] SHI T B, CHEN W J, GAO C J, et al. Yarn tensile experiments and numerical simulations based on the decomposition of stratospheric airship envelopes[J]. Journal of Aerospace Engineering, 2018, 31(3): 04018011 doi: 10.1061/(ASCE)AS.1943-5525.0000833 [5] LIU Y, SUN K W, XU Z Y, et al. Energy efficiency assessment of photovoltaic array on the stratospheric airship under partial shading conditions[J]. Applied Energy, 2022, 325(4): 119898 [6] JIAO J, SONG B F, ZHANG Y G, et al. Optimal design and experiment of propellers for high altitude airship[J]. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 2018, 232 (10): 1887-1902 [7] ZHANG H, FUJIKI K, IDO K, et al. Tensile testing of freestanding polymer thin films with non-standard geometries[J]. Polymer Testing, 2020, 91: 106825 doi: 10.1016/j.polymertesting.2020.106825 [8] LIN X T, WU Y C, CHEN X, et al. Structural evolution and properties of polyamide‐6/ poly (ether block amide) films during the simultaneous biaxial stretching[J]. Journal of Applied Polymer Science, 2022, 139(19): 52152 doi: 10.1002/app.52152 [9] WANG F X, CHEN Y L, LIU G Z, et al. Investigation of the tearing properties of a new airship envelope fabric based on experimental and theoretical methods[J]. Journal of Industrial Textiles, 2019, 48(8): 1327-1347 doi: 10.1177/1528083718754904 [10] BAYAZIAN H, YADEGARI A, SCHÖPPNER V. Probing tensile properties of LLDPE stretch films prepared in cast extrusion process[J]. Polymer Bulletin, 2022, 79(3): 1873-1886 doi: 10.1007/s00289-021-03599-9 [11] WANG F X, CHEN Y L, LIU G Z, et al. Experimental investigation and theoretical analysis of tear propagation of GQ-6 airship envelope[J]. Journal of Industrial Textiles, 2018, 48(1): 304-321 doi: 10.1177/1528083716685906 [12] 张祎贝, 陈务军, 邓小伟, 等. 薄膜结构空气与低真空环境下模态辨识仿真及试验[J]. 振动与冲击, 2020, 39(20): 168-174,182ZHANG Yibei, CHEN Wujun, DENG Xiaowei, et al. Simulation and experiment for membrane modal identification in the air and low vacuum environment[J]. Journal of Vibration and Shock, 2020, 39(20): 168-174,182 [13] CHEN Y L, YANG W D, XIE W C, et al. Meso-Scale tearing mechanism analysis of flexible fabric composite for stratospheric airship via experiment and numerical simulation[J]. Journal of Shanghai Jiaotong University (Science), 2022, 27(6): 873-884 doi: 10.1007/s12204-022-2431-8 [14] 陈建稳, 周涵, 陈务军, 等. 飞艇用层压织物膜材料在双向应力作用下的弹性参数分析[J]. 上海交通大学学报, 2017, 51(03): 344-352CHEN Jianwen, ZHOU Han, CHEN Wujun, et al. Analysis of elastic parameters for laminated fabrics used in airships under biaxial stresses[J]. Journal of Shanghai Jiao-Tong University, 2017, 51(03): 344-352 [15] 彭冬冬. 橡胶材料双向拉伸试样有限元分析及其真双轴拉伸试验装置设计[D]. 青岛: 青岛科技大学, 2020PENG Dongdong. Finite element analysis of rubber biaxial tensile specimen and design of its true biaxial tensile test device[D]. Qingdao: Qingdao University of Science and Technology, 2020 [16] 王靖义. 薄膜结构基于附加质量的振动特性分析[D]. 哈尔滨: 哈尔滨工业大学, 2021WANG Jingyi. Analysis of vibration characteristics of thin structure based on additional mass[D]. Harbin: Harbin Institute of Technology, 2021 -

-

程靖淞:男, 1997年7月出生于山西省朔州市, 现为中国科学院空天信息创新研究院硕士研究生, 主要研究方向为平流层飞艇动力学特性、结构动力学仿真与分析等. E-mail:

程靖淞:男, 1997年7月出生于山西省朔州市, 现为中国科学院空天信息创新研究院硕士研究生, 主要研究方向为平流层飞艇动力学特性、结构动力学仿真与分析等. E-mail:

下载:

下载: