Experiments and Simulations on 3D Printed High Temperature Titanium Water Heat Pipe

-

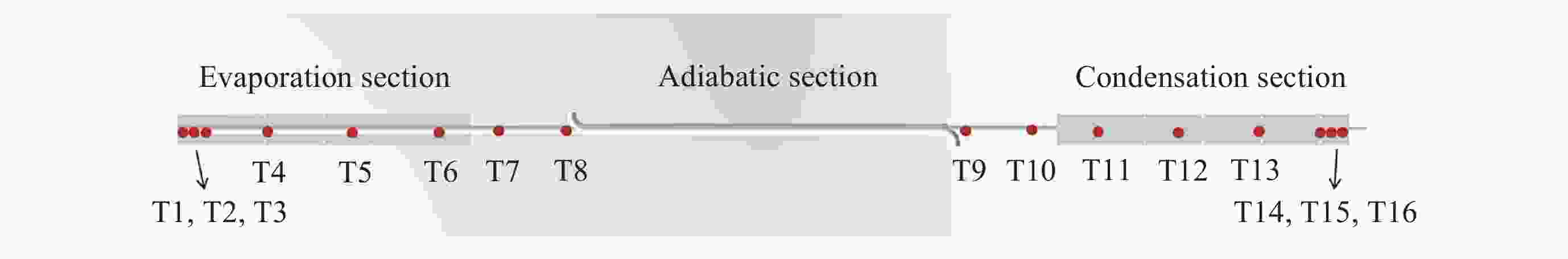

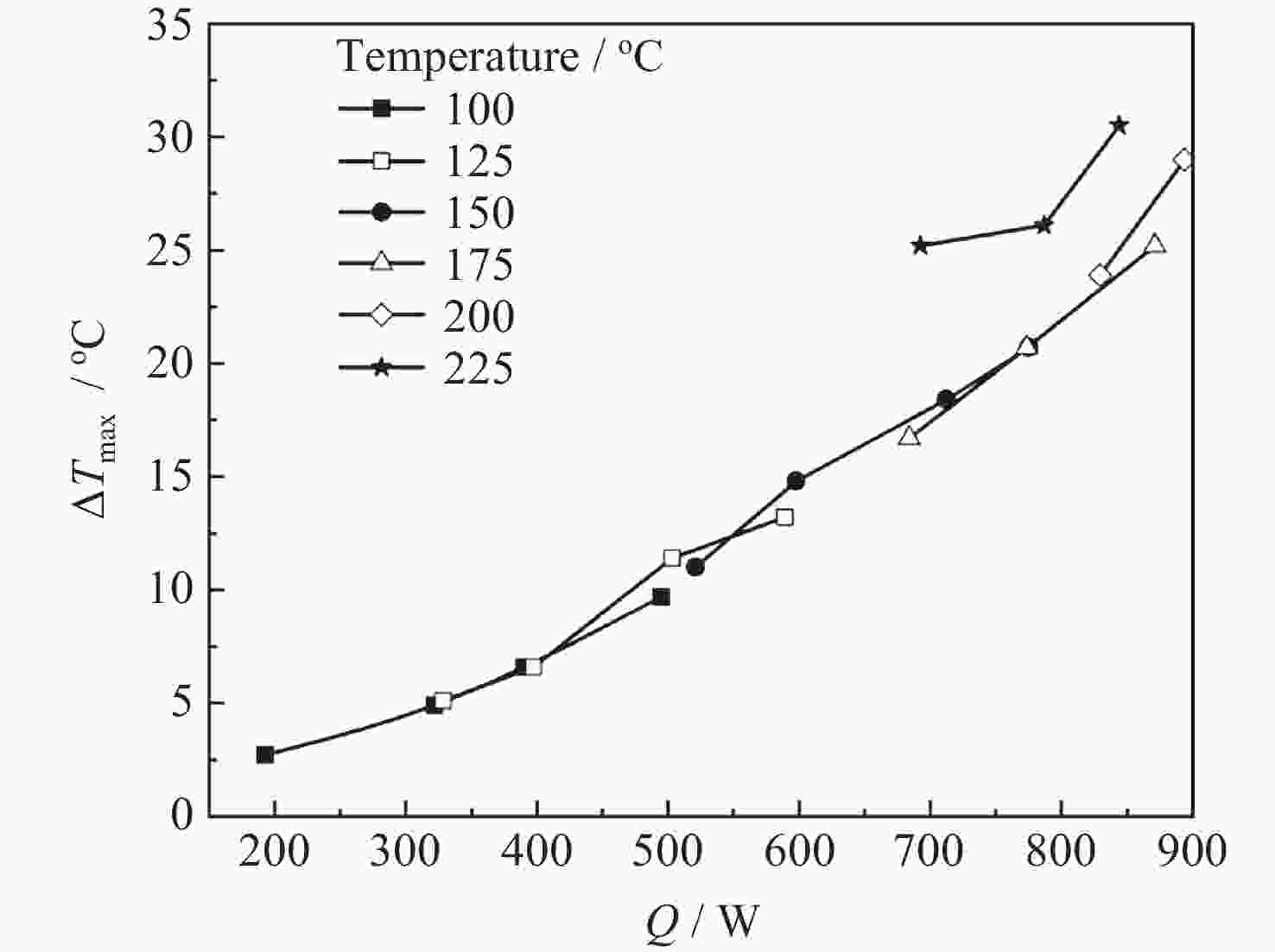

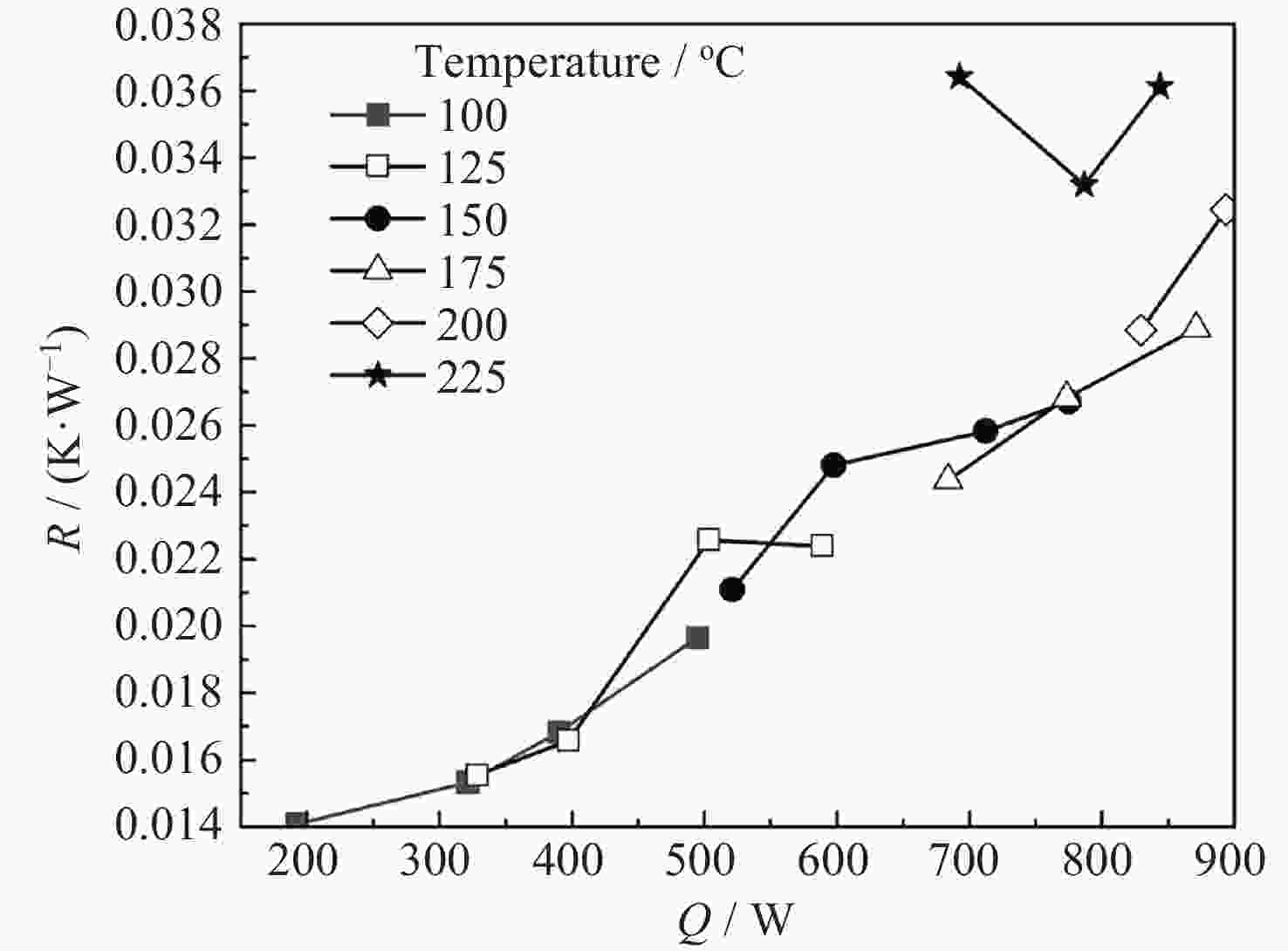

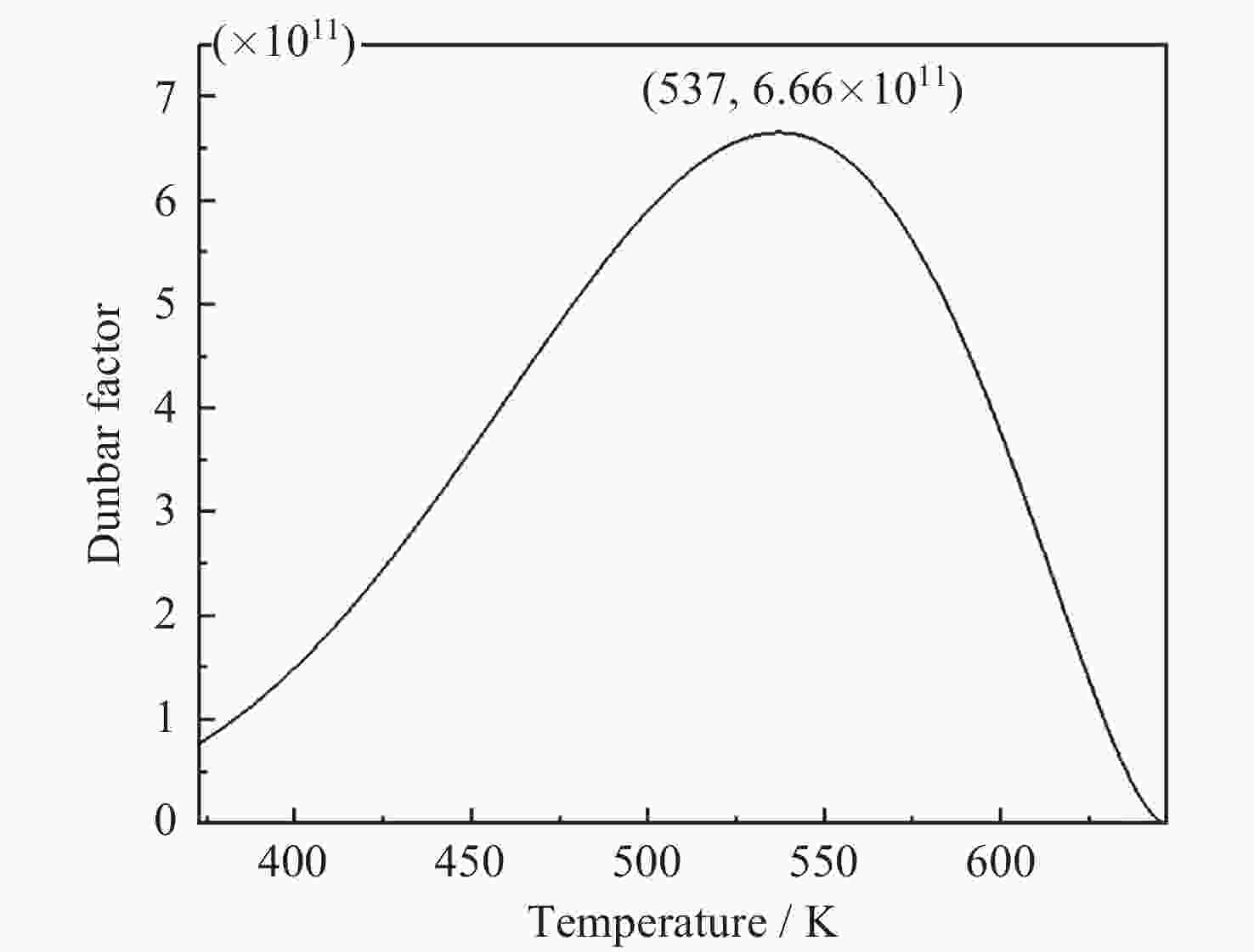

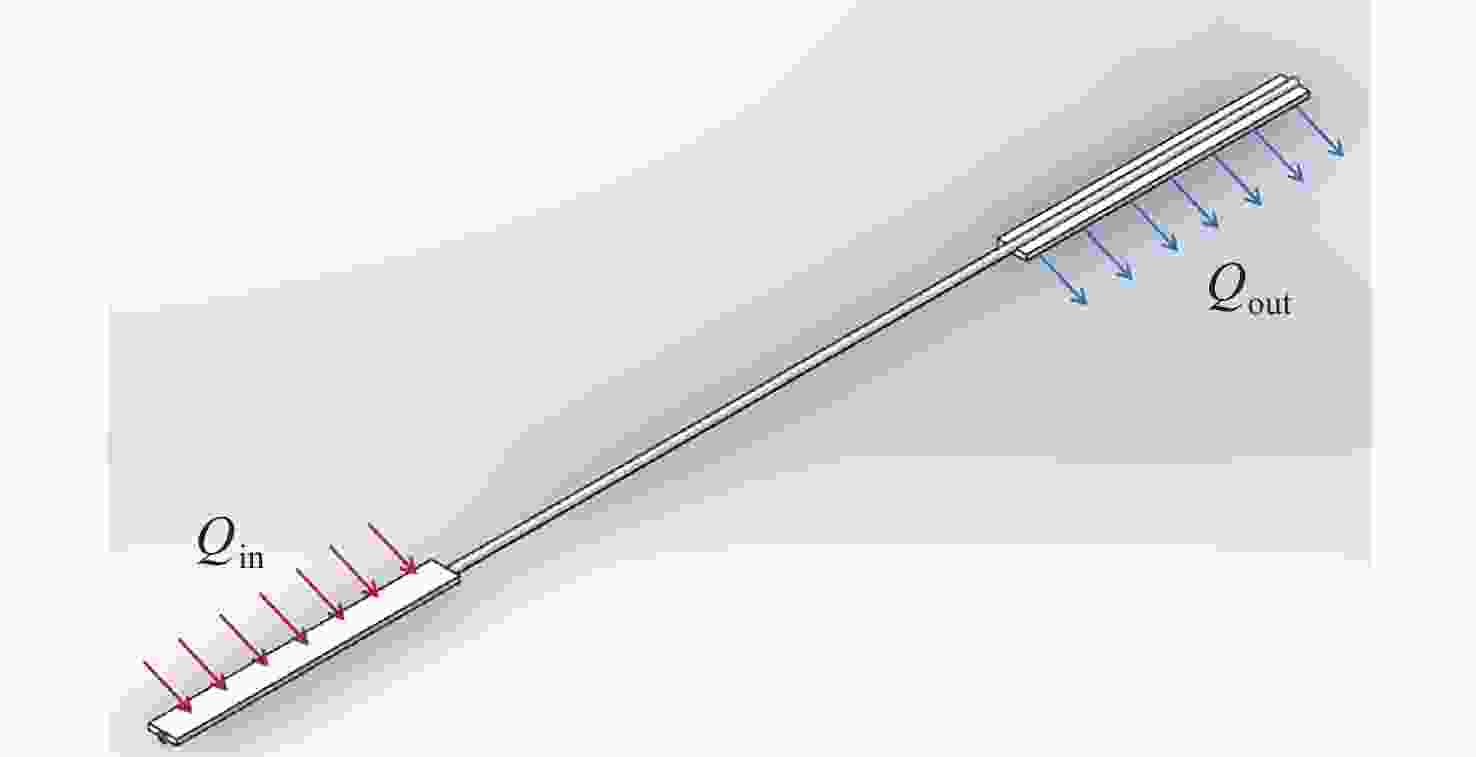

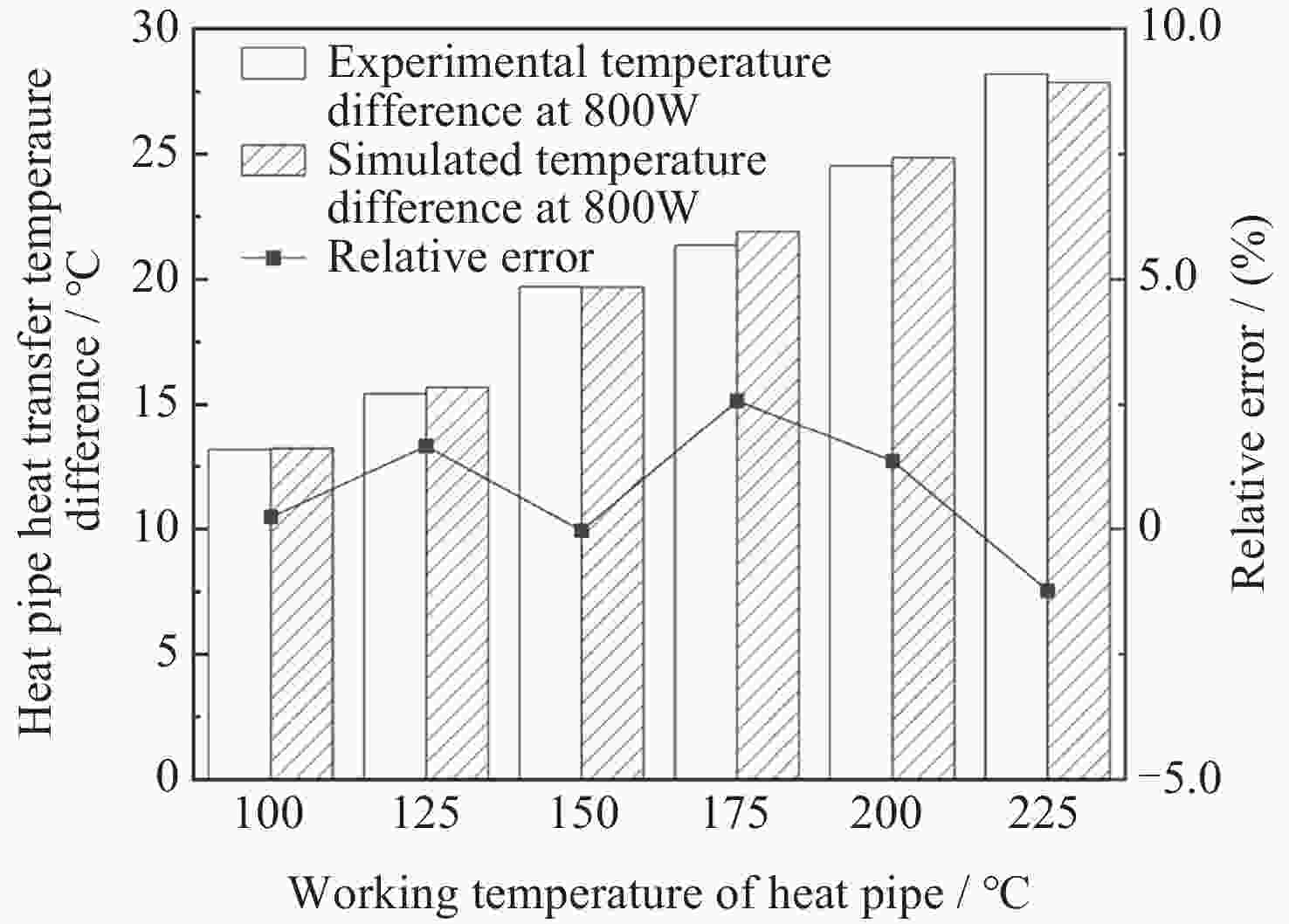

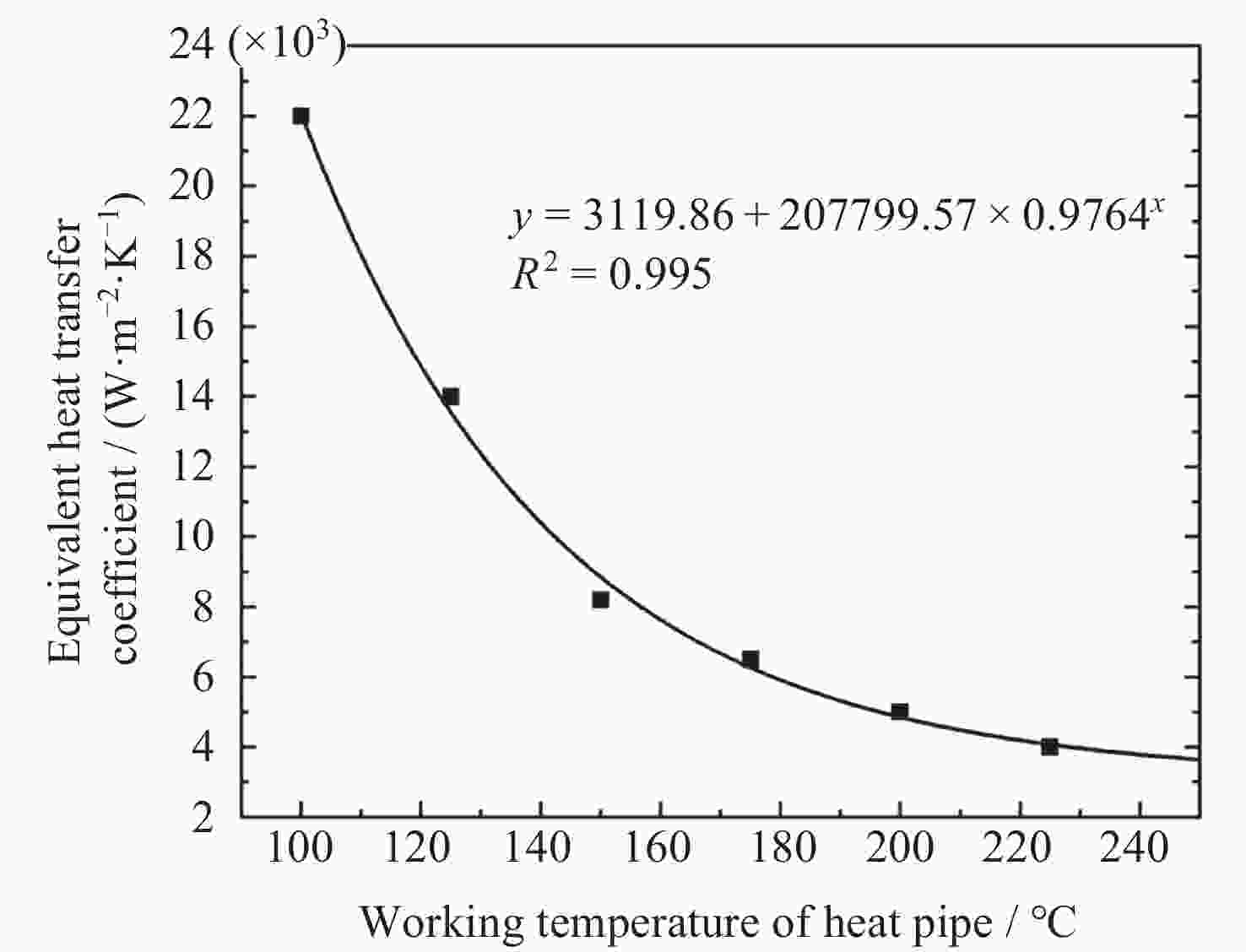

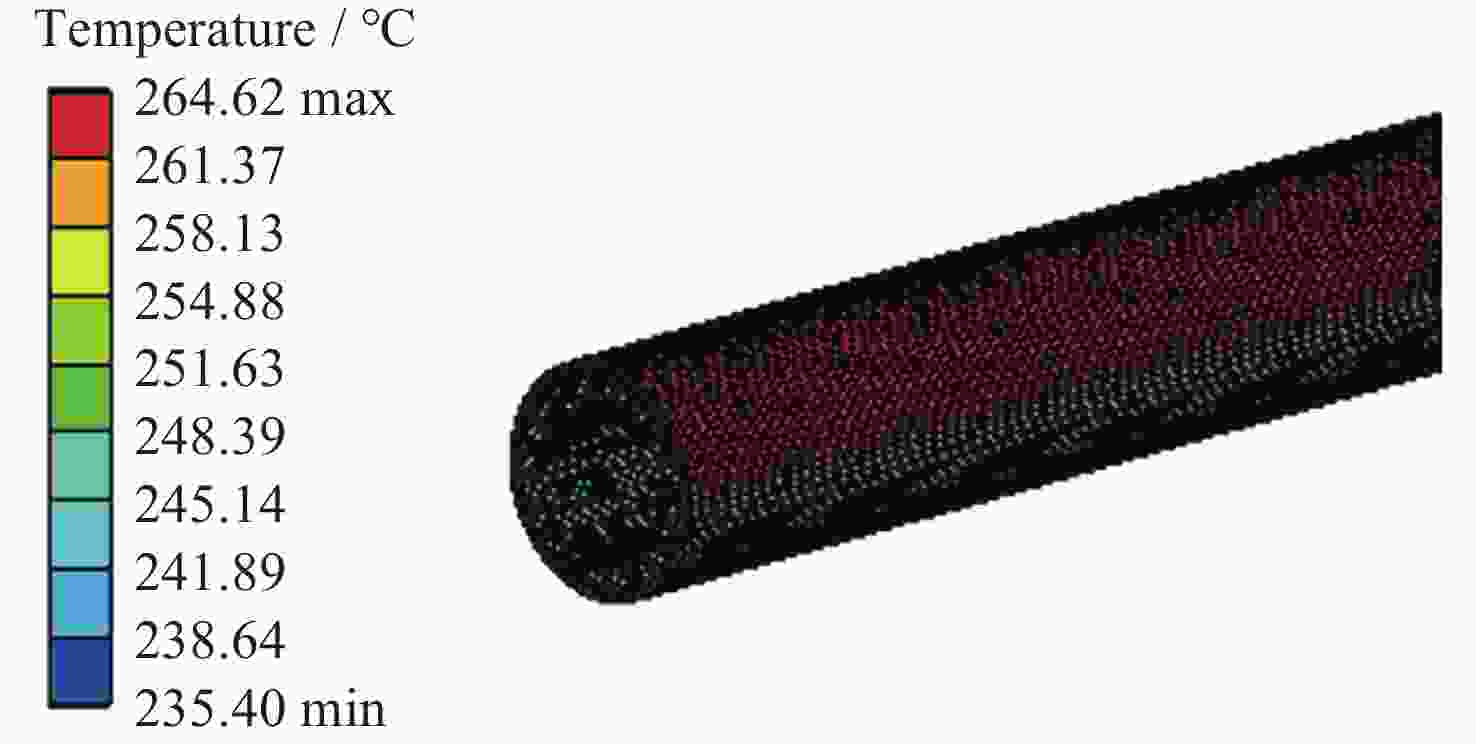

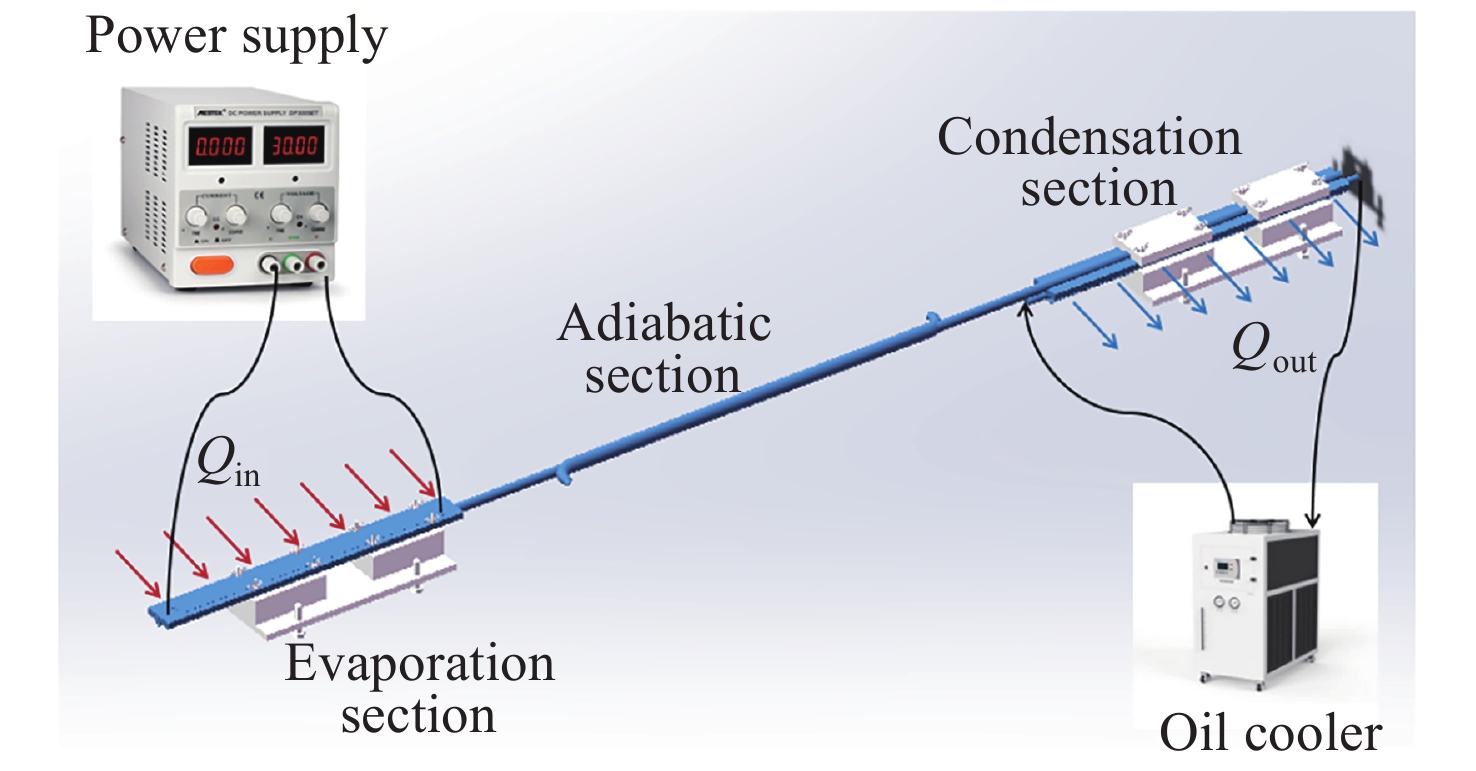

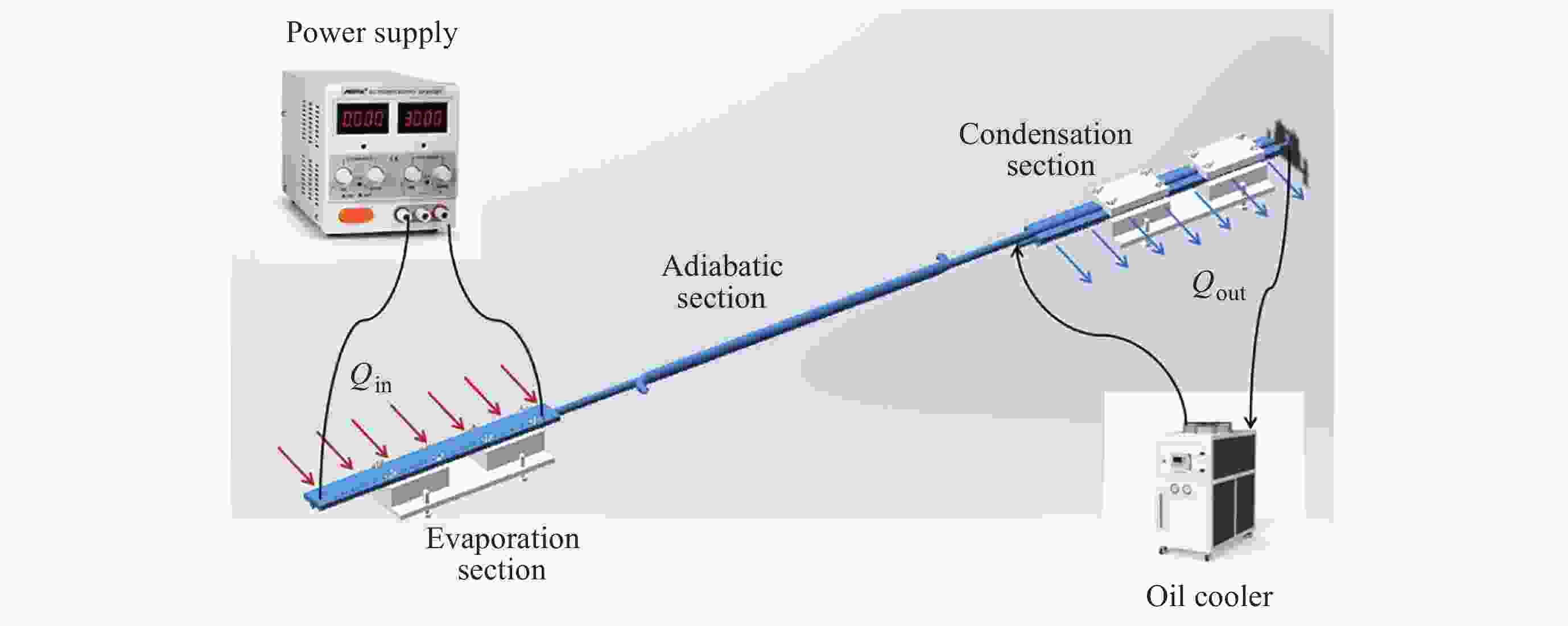

摘要: 未来星际航行对高温工况下的废热排散提出了更高的要求. 当前辐射器设计越来越依赖热管, 高温环境下具有高导热性的钛水热管, 可以有效传递热量, 并且最大限度缩减辐射器的面积. 本文针对3D打印的钛水热管进行了传热性能实验与仿真研究. 在100~225℃的工作温度范围内, 通过向热管施加不同的加热功率, 研究钛水热管的传热能力. 实验结果表明, 钛水热管的最大传热温差随加热功率的增大而增加, 钛水热管在200℃时最大传热功率为893.9 W. 在实验测试的基础上开展仿真研究, 得到钛水热管的等效换热系数随温度的变化规律, 并预测250℃下其等效换热系数为3650 W·m–2·K–1), 传热温差为29.22℃.Abstract: Future interstellar navigation will demand new energy. The thrust of spacecraft using chemical fuels is difficult to sustain, and a suitable launch window must be found for each launch in order to utilize the planet's gravity for acceleration. Traditional solar panels are far from meeting the energy requirements for manned interstellar travel and must rely on the effective and stable supply of new energy power systems. The propulsion system of new energy powered spacecraft can carry a larger payload, enter planetary orbit and return to the ground in a more flexible and efficient manner, but also poses higher requirements for waste heat dissipation at high temperatures. Heat pipe technology is an important technical means to achieve efficient and long-distance heat transfer in medium and high temperature zones (100~300℃). The current radiator design increasingly relies on heat pipes. Titanium water heat pipes with high thermal conductivity at high temperatures can effectively transfer heat and raise the radiation temperature, thus minimize the area of the radiator. Experiments and simulations on the 3D printed titanium water heat pipe were conducted. Applying different heating powers at 100~225℃, the heat transfer capacity of the titanium water heat pipe was studied. The results show that the maximum heat transfer temperature difference of the titanium water heat pipe increases with the increase of heating power. The maximum heat transfer power of titanium water heat pipe at 200℃ is 893.9 W, and analysis shows that the maximum heat transfer power of titanium water heat pipes is greater than 893.9 W at 200~264℃. Based on experiments, simulations were conducted to obtain the variation of the equivalent heat transfer coefficient of titanium water heat pipes with temperature. The equivalent heat transfer coefficient at 250℃ is predicted to be 3650 W·m–2·K–1, with a heat transfer temperature difference of 29.22℃.

-

表 1 钛水热管性能实验工况

Table 1. Experimental conditions for performance of titanium water heat pipes

绝热段温度/℃ 加热功率/W 100 200, 300, 400, 500 125 300, 400, 500, 600 150 500, 600, 700, 800 175 700, 800, 900 200 850, 900 225 700, 800, 850 -

[1] ZHANG Ze, XUE Xiang, WANG Yuanding, et al. Prospect of space nuclear power propulsion technology[J]. Journal of Rocket Propulsion, 2021, 47(5): 1-13 (张泽, 薛翔, 王园丁, 等. 空间核动力推进技术研究展望[J]. 火箭推进, 2021, 47(5): 1-13ZHANG Ze, XUE Xiang, WANG Yuanding, et al. Prospect of space nuclear power propulsion technology[J]. Journal of Rocket Propulsion, 2021, 47(5): 1-13 [2] LEE K L, ANDERSON W G, TARAU C. Titanium-water heat pipe radiators for kilopower system cooling applications[C]//International Energy Conversion Engineering Conference. Cincinnati, Ohio: AIAA, 2018 [3] Lee K L , Tarau C , Anderson W G , et al. Titanium-Water Heat Pipe Radiators for Space Fission Power System Thermal Management[J]. Microgravity Science and Technology, 2020, 32(3). DOI: 10.1007/s12217-020-09780-5 [4] CHEN Jie, GAO Shaolun, XIA Chenchao, et al. Study on space nuclear power technological option[J]. Aerospace Shanghai, 2019, 36(6): 1-10 (陈杰, 高劭伦, 夏陈超, 等. 空间堆核动力技术选择研究[J]. 上海航天, 2019, 36(6): 1-10 doi: 10.19328/j.cnki.1006-1630.2019.06.001CHEN Jie, GAO Shaolun, XIA Chenchao, et al. Study on space nuclear power technological option[J]. Aerospace Shanghai, 2019, 36(6): 1-10 doi: 10.19328/j.cnki.1006-1630.2019.06.001 [5] WANG Zhao, XIA Chenchao, KANG Zhiyu, et al. Design and key technologies of modular nuclear powered spacecrafts[J]. Aerospace Shanghai, 2019, 36(6): 141-147 (王钊, 夏陈超, 康志宇, 等. 模块化核动力航天器设计及其关键技术[J]. 上海航天, 2019, 36(6): 141-147 doi: 10.19328/j.cnki.1006-1630.2019.06.020WANG Zhao, XIA Chenchao, KANG Zhiyu, et al. Design and key technologies of modular nuclear powered spacecrafts[J]. Aerospace Shanghai, 2019, 36(6): 141-147 doi: 10.19328/j.cnki.1006-1630.2019.06.020 [6] ZHOU Tao. Research on Design Optimization Technology of Loop Heat Pipe Radiator in Space Reactor[D]. Harbin: Harbin Engineering University, 2023 (周涛. 空间堆环路热管辐射散热器设计优化技术研究[D]. 哈尔滨: 哈尔滨工程大学, 2023ZHOU Tao. Research on Design Optimization Technology of Loop Heat Pipe Radiator in Space Reactor[D]. Harbin: Harbin Engineering University, 2023 [7] HAINLEY D C. User's Manual for the Heat Pipe Space Radiator Design and Analysis Code (HEPSPARC)[R]. Brook Park: NASA Lewis Research Center Group, 1991 [8] GROVER G M, COTTER T P, ERICKSON G F. Erratum: structures of very high thermal conductance[J]. Journal of Applied Physics, 1964, 35(10): 3072-3072 doi: 10.1063/1.1713185 [9] ENKE C, JÚNIOR J B, VLASSOV V. Transient response of an axially-grooved aluminum-ammonia heat pipe with the presence of non-condensable gas[J]. Applied Thermal Engineering, 2021, 183: 116135 doi: 10.1016/j.applthermaleng.2020.116135 [10] ANDERSON W G, BIENERT W. Loop heat pipe radiator trade study for the 300-550 K temperature range[J]. AIP Conference Proceedings, 2005, 746(1): 946-953 [11] SANZI J L, JAWORSKE D A. Heat Pipes and Heat Rejection Component Testing at NASA Glenn Research Center[R]. Cleveland: Glenn Research Center, 2012 [12] ROSENFELD J H, GERNERT N J. Advances in high temperature titanium-water heat pipe technology[J]. AIP Conference Proceedings, 2007, 880(1): 129-136 doi: 10.1063/1.2437449 [13] ROSENFELD J H, GERNERT N J. Life test results for water heat pipes operating at 200 ℃ to 300 ℃[J]. AIP Conference Proceedings, 2008, 969(1): 123-130 doi: 10.1063/1.2844957 [14] FENG Maolong, LAI Xiaoyi, HAN Haiying et al. Study on radiation performance of fluid loop-heat pipe coupled radiator for China space station[J]. Aerospace Shanghai (Chinese :Times New Roman;">& English), 2023, 40(5): 88-93 (丰茂龙, 来霄毅, 韩海鹰, 等. 空间站流体回路/热管耦合式热辐射器性能研究[J]. 上海航天(中英文), 2023, 40(5): 88-93 doi: 10.19328/j.cnki.2096-8655.2023.05.012FENG Maolong, LAI Xiaoyi, HAN Haiying et al. Study on radiation performance of fluid loop-heat pipe coupled radiator for China space station[J]. Aerospace Shanghai (Chinese & English), 2023, 40(5): 88-93 doi: 10.19328/j.cnki.2096-8655.2023.05.012 [15] ZHANG Xiu, ZHANG Haochun, LIU Xiuting, et al. Thermal analysis and parameter optimization of a heat-pipe radiator for space nuclear power[J]. Journal of Astronautics, 2019, 40(4): 452-458 (张秀, 张昊春, 刘秀婷, 等. 空间核电源热管式辐射散热器热分析与参数优化[J]. 宇航学报, 2019, 40(4): 452-458ZHANG Xiu, ZHANG Haochun, LIU Xiuting, et al. Thermal analysis and parameter optimization of a heat-pipe radiator for space nuclear power[J]. Journal of Astronautics, 2019, 40(4): 452-458 [16] BEARD D, ANDERSON W G, TARAU C, et al. High temperature water heat pipes for kilopower system[C]//15th International Energy Conversion Engineering Conference. Atlanta: AIAA, 2017 [17] LEE K L, KADAMBI J R, KAMOTANI Y. The influence of non-condensable gas on an integral planar heat pipe radiators for space applications[J]. International Journal of Heat and Mass Transfer, 2017, 110: 496-505 doi: 10.1016/j.ijheatmasstransfer.2017.03.060 [18] ZHOU Qiang, WANG Lu, LIU Chang, et al. Design and verification of 3D printing titanium-water heat pipe used in high power spacecraft[J]. Spacecraft Engineering, 2020, 29(4): 86-92 (周强, 王录, 刘畅, 等. 用于大功率航天器的3D打印钛水热管设计及试验研究[J]. 航天器工程, 2020, 29(4): 86-92 doi: 10.3969/j.issn.1673-8748.2020.04.013ZHOU Qiang, WANG Lu, LIU Chang, et al. Design and verification of 3D printing titanium-water heat pipe used in high power spacecraft[J]. Spacecraft Engineering, 2020, 29(4): 86-92 doi: 10.3969/j.issn.1673-8748.2020.04.013 [19] FLEMING A J, THOMAS S K, YERKES K L. Titanium-water loop heat pipe operating characteristics under standard and elevated acceleration fields[J]. Journal of Thermophysics and Heat Transfer, 2010, 24(1): 184-198 doi: 10.2514/1.45684 [20] TIAN Zhixing, LIU Xiao, WANG Chenglong, et al. Study on heat transfer performance of high temperature potassium heat pipe at steady state[J]. Atomic Energy Science and Technology, 2020, 54(10): 1771-1778 (田智星, 刘逍, 王成龙, 等. 高温钾热管稳态运行传热特性研究[J]. 原子能科学技术, 2020, 54(10): 1771-1778TIAN Zhixing, LIU Xiao, WANG Chenglong, et al. Study on heat transfer performance of high temperature potassium heat pipe at steady state[J]. Atomic Energy Science and Technology, 2020, 54(10): 1771-1778 [21] DUNBAR N, CADELL P. Working fluids and figure of merit for CPL/LHP applications[C]//CPL-98 Workshop. El Segundo: The Aerospace Corporation, 1998 -

-

王慧志 男, 1992年4月出生于河南省周口市, 现为北京空间飞行器总体设计部高级工程师, 主要研究方向为航天器热控技术. E-mail:

王慧志 男, 1992年4月出生于河南省周口市, 现为北京空间飞行器总体设计部高级工程师, 主要研究方向为航天器热控技术. E-mail:

下载:

下载: